| Date Published | September 19, 2013 |

| Company | Logan Completion Systems |

| Article Author | Logan Completion Systems |

| Article Type | June 2013 Issue |

| Category | Articles |

| Tags | Casing Patches, Completion Tools, Custom Tool Design & Development, Flow Control, Liner Hangers, Mud Motors, MultiStim Fracture Isolation Systems, Oilfield HUB Member, Open Hole Packers, Retrievable & Permanent Packers, Service Tools, Thermal Completions, Thermal Liner Hangers |

| HUB SEARCH | Logan |

| Downloads |

|

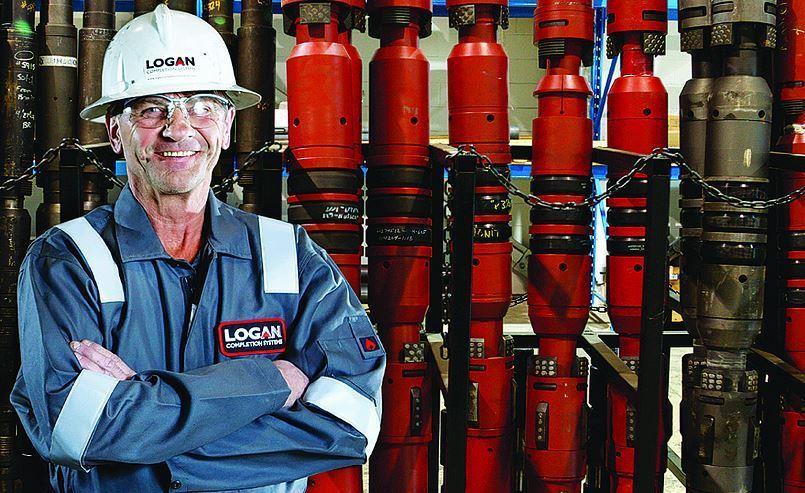

Logan Completion Systems (LCS), is an innovative oil and gas service company with operations in Canada, the United States, and the international market. LCS provides high-quality equipment, and remedial and stimulation services to the unconventional oil and gas fracturing markets, along with a comprehensive line of completion products that includes conventional, thermal, well construction, and other multi-zone completion products and services.

Logan International Inc. acquired the Canadian companies — Source Energy Tool Services Inc. and Complete Oil Tools Inc. — in May and August of 2010, respectively. These wholly-owned subsidiaries of Logan International merged and were renamed “Logan Completion Systems†in 2011. This name change aligned the Corporation and its operating subsidiaries under the world recognized LOGAN brand.

Headquartered in Calgary, Canada, Logan Completion Systems complements the other companies in Logan International’s downhole tool segment — Logan Oil Tools, Dennis Tool Company, Kline Tools, Logan Scope, and Logan Xtend — and enhances its offerings to Logan International’s customers by combining its products and services.

Logan Completion Systems’ proprietary multi-stage fracturing technology is used in horizontal wells and is unique in the marketplace. Logan’s technology facilitates the removal of the balls and seats post-fracturing, and leaves a fully-open wellbore that increases production flow capacity and allows easier downhole intervention without the need for costly and debris-creating milling or drilling to remove the seats.

Most of Logan’s competitors leave the seats in the well and produce the well with these restrictions remaining in place. The problem is that these ball seats limit the full production potential of the reservoir. Logan’s competitors recommend to their clients that they remove the ball seats by drilling them up, or alternatively, to simply leave them in place. But the problem with the drilling process is that all of those ball seats are converted into debris that contaminates the wellbore and, in some cases, reduces well production rates.

MultiStim Fracture Isolation Systems have been specifically designed for multi-stage fracs. They feature valves with fully removable seats post-fracturing via threaded tubing with-out milling or drilling. Rather than milling the balls and ball seats, MultiStim technology removes the ball seats from the sleeve, and can either bring them back to the surface or leave them at the bottom of the wellbore. The advantages are time savings and the reduction of debris created from the drilling process. With the MultiStim system, seats can be removed with fewer problems and quite a bit less debris. It gives Logan’s customers more options in how to produce the well.

MultiStim technology, which has been used extensively throughout Western Canada, has been well received since it was introduced to the market more than two-and-a-half years ago.

Logan Completion Systems Offers a Comprehensive Line of Completion Products:

MultiStim Fracture Isolation Systems

Casing Patches

Open Hole Packers

Completion Tools

Retrievable & Permanent Packers

Mud Motors

Service Tools

Flow Control

Liner Hangers

Thermal Liner Hangers

Thermal Completions

Custom Tool Design & Development