| Date Published | March 30, 2017 |

| Company | Oilfield HUB |

| Article Author | Dave O’Connor |

| Article Type | March 2017 Issue |

| Category | Articles, Oilfield HUB |

| Tags | FCM - Field Cost Manager, Oilfield HUB Suite, ORM - Operations Report Manager, Procurement Practices, PVM-Preferred Vendor Manager, VRM - Vendor Relationship Manager |

| HUB SEARCH | OilfieldHUB |

IT IS SOMETHING of a conundrum that although the oil and gas business is highly dependent on technology, the industry is typically slow to adopt the latest innovations. The reasons are many, including inertia, the fear of fixing something that isn’t broken or simple complacency. Given the large sums of capital at risk in the oil business, avoiding uncertainty is understandable. However, sometimes being just “good enough” is the enemy of making advancements in productivity, cost savings, and improving financial returns.

Since the shale revolution began in 2006, the industry has readily adopted innovations in hardware technology needed to drill and complete horizontal wells to develop resource plays. Powerful top drives, high pressure mud pumps, “walking” rigs and other improvements in oilfield equipment were rapidly developed and deployed into service. These improvements have reduced drilling days, and increased recoveries.*

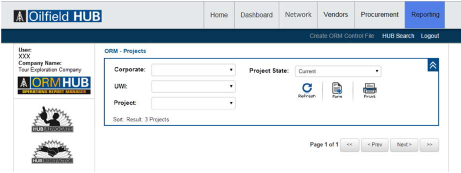

In the last two years, we introduced a powerful new daily field reporting service module into our web-based Oilfield HUB suite of products. The industry needs it. However, in the process of working with Producer and EPC companies we have learned that there is a much bigger problem plaguing the oil & gas industry. Poor procurement and sourcing practices. All companies from micro juniors to majors have told us they believe their cost of sales are still too high. They are having issues and need help getting vendor management and purchasing policies and procedures more organized, verifiable and audit proof. Our finding is that poor vendor management leads to escalating costs and reduced profitability. Our mission this year is to reduce these costs.

If the first wave of innovation was based on improving “dumb iron,” then this second wave of innovation is about using smart information technology to do things faster, better, and more productively. In the field, operators are improving recoveries by using technology-based solutions to drill more accurately and optimize completions. At headquarters, business development teams are leveraging cloud-based solutions to identify and act on new prospects in days, rather than weeks or months.

*originally published on ogfj.com

Oilfield HUB is a revolutionary suite of operations tools that centralizes information from pin to pipeline. Our belief is that by implementing a quality management system for procurement, sourcing, and field reporting that offers more transparency and efficiency between head office, field personnel and preferred vendors, costs will be reduced.

Dave O’Connor

Vice President – Sales

dave.oconnor@oilfieldhub.com

(403) 910-4172

OILFIELD HUB Inc.