| Date Published | September 18, 2013 |

| Company | Ecoquip Pump Jacks |

| Article Author | Markham Hislop |

| Article Type | June 2013 Issue |

| Category | Articles, Cover Story |

| Tags | Advantage Custom Cover, Oilfield HUB Member, Pump Jacks |

| HUB SEARCH | Ecoquip |

| Downloads |

|

A lot of Western Canada’s oil is hard to get to. Whether it’s tight oil in the Bakken Formation, the oil sands of northern Alberta, or heavy oil around Lloydminster, Canadians have brainstormed new ways to produce unconventional crude oil.

One of the technologies that emerged from Western Canada is the hydraulic pump jack.

Everyone is familiar with that old standby of oilfield production, the pump jack, with its distinctive horse-head nodding up and down, day and night, powering the pump located thousands of feet beneath the surface. There are thousands of oil wells in the West and many of them will be produced using pump jacks.

Sometimes, the simple pump jack isn’t the best option.

In that case, producers are turning more and more to hydraulic pump jacks like the ones manufactured, distributed and serviced by Ecoquip Rentals and Sales Ltd. Oil patch veteran Les Grabill and his partner Glen Schultz founded the company in Calgary in 1992. Grabill found himself laid off for the first time in 28 years and decided to turn bad luck into a good opportunity. He started selling used oilfield equipment and did well. But as luck would have it, a couple of inventors with a new idea for a hydraulic pump jack stumbled across his path and he was intrigued by their concept.

Over a period of 7 years, Les Grabill and Glen Schultz took over the development of the pump jack amongst other business activities, but decided to go fully commercial with the pump jacks in 2000. Les has since entered semi-retirement in 2006, but eldest son Tim remains as President of the operating company and has been involved with the expansion of the company since 2002, while his other son Chris came on board in 2006 and serves as Vice-President of Operations.

Over a period of 7 years, Les Grabill and Glen Schultz took over the development of the pump jack amongst other business activities, but decided to go fully commercial with the pump jacks in 2000. Les has since entered semi-retirement in 2006, but eldest son Tim remains as President of the operating company and has been involved with the expansion of the company since 2002, while his other son Chris came on board in 2006 and serves as Vice-President of Operations.

How does an Ecoquip hydraulic pump jack work? Pretty much like a car’s braking system. Press your car’s brake pedal and fluid moves from the master cylinder to the wheel cylinders. Release the pedal and the fluid flows back to the master cylinder. Something similar happens with the Ecoquip hydraulic pump jack.

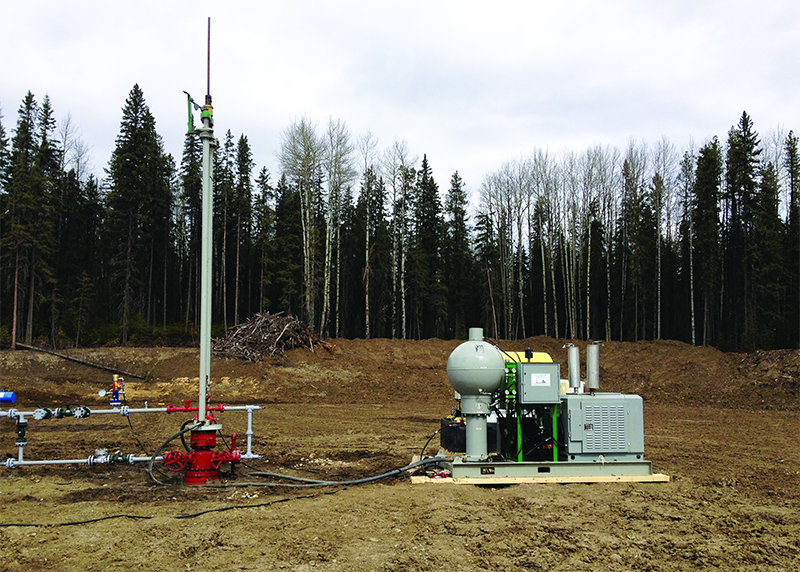

The system has two primary components: the slave cylinder that mounts on the wellhead and a skid-mounted power unit. The power unit contains a master cylinder with four chambers, two slave cylinders that move the polish rod, a positive displacement swash plate-type hydraulic pump, motor and control panel.

Chamber A in the master cylinder displaces fluid to the slave cylinders, forcing them to rise as the master cylinder piston moves downward. Chambers B and C add energy to the system. Chamber D is the accumulator and stores pressurized nitrogen, which stores energy as the polish rod moves down, then uses that energy to help move the polish rod during the upward stroke.

Les Grabill says the Ecoquip system replaces the old-style method of using a valve to reverse the fluid flow when changing from one stroke direction to the other. That system created pressure spikes and heat that over time (sometimes not much of it), caused the system to prematurely fail.

That’s why in the early days, customers mostly wanted to rent rather than buy hydraulic pump jacks. Renting made sense for early adopters, minimizing their risk and giving them a chance to become familiar with the technology. In theory, if the new widget doesn’t work as advertised, the producer can always give it back and stop the rental payments.

Fortunately for Ecoquip, the rentals were a big hit with customers. Ecoquip has seen a trend that as the hydraulic pump jacks proved themselves; customers were more inclined to buy rather then rent.

“We started out thinking we were always going to rent and act like a service company, but companies saw the value and pushed us to build more and sell. Five years ago I would have said we had 35% of our fleet sold and 65% rented. Now it’s flipped, if not higher than 65% sold,†Chris Grabill said, “More companies are comfortable buying our units and moving them, servicing them themselves, finding the use and reliability of them very beneficial.â€

The rental model was also good for Ecoquip because it provided cash flow and allowed the company to cautiously develop the technology, test it and prove it without the need to rush it into the marketplace.

Ecoquip’s hydraulic pump jacks have four major advantages over competitors:

The company is poised for a significant expansion over the next few years. Now that the development and testing phases of the hydraulic pump jack have been proven over 15 years and the product has been well accepted in the Western Canadian market, the time has come to get serious about building out their dealer network and exploring new markets.

“We have a dealer in Manning, Alberta, Leading Edge, who has their own rental fleet of our pump jacks and takes care of rental and sold units north of Grand Prairie and I’d like to replicate that type of relationship in Saskatchewan and North Eastern Alberta,†says Tim. “The Bakken area, as everyone knows, is blowing up and the best way for us to get in there is not to set up a branch, but to give the knowledge base to some local providers and give them the opportunity to represent our equipment.â€

Ecoquip has had plenty of interest from international customers and exporting is definitely in the company’s future.

“In Canada, we’ve just scratched the marketplace that is there†explains Chris. “We have not expanded into the international market yet, which is a huge opportunity. I feel the Ecoquip hydraulic pump has a budding opportunity at this stage.â€

“We have the 9000-6 unit that is a really good fit for many applications because it covers such a wide range of other conventional pump jacks. The power unit is about the size of a small sedan,†says Tim. “It compares to a number of conventional pump jacks from 114 to 912 pump jacks, we’re significantly smaller but equally as powerful. With our recent developments we have further increased our stroke length to 158â€, SPM can range from less than 1spm to greater than 8spm depending on stroke length with polish rod loads up to 35,000 lbs. And we’re also easily mobile, which is a big advantage for producers in remote areas. Sizing of pump jacks has become a thing of the past when we can offer so much in one unit.â€

With Steam Assisted Gravity Drainage slowly becoming a prominent method of production in the Alberta oil sands, Ecoquip expects SAGD to become a larger market. “We also have a 9000-9 unit that can do a 240†stroke and PRL of 60,000 lbs. and has all the features and power of our other units. This long, controllable, reliable stroke is the best option for pumping oil sands applications,†says Chris.

For lower producing wells, Ecoquip is working on a smaller design which will meet the price point for this market but still give their customers the reliability and service they have become familiar with.

Ecoquip is a classic Canadian oil patch story of innovation and perseverance. After 20 years innovating, testing, renting, selling and servicing under founder Les Grabill, the company is ready for a major expansion under his sons Tim and Chris.